Pellet Equipment

Conventional snack categories are experiencing some fierce competition from pellet, co-extruded, air-popped and other vegetable-based snacks, which some call “new age snacks.”

While pellet snacks are conventionally made with potato or cereal-based flours, atypical blends can mix pulses with fortified vegetable powders to enhance a nutrition facts panel. This type of snack caught the attention of consumers in Europe and the Middle East before making an impact in the U.S.

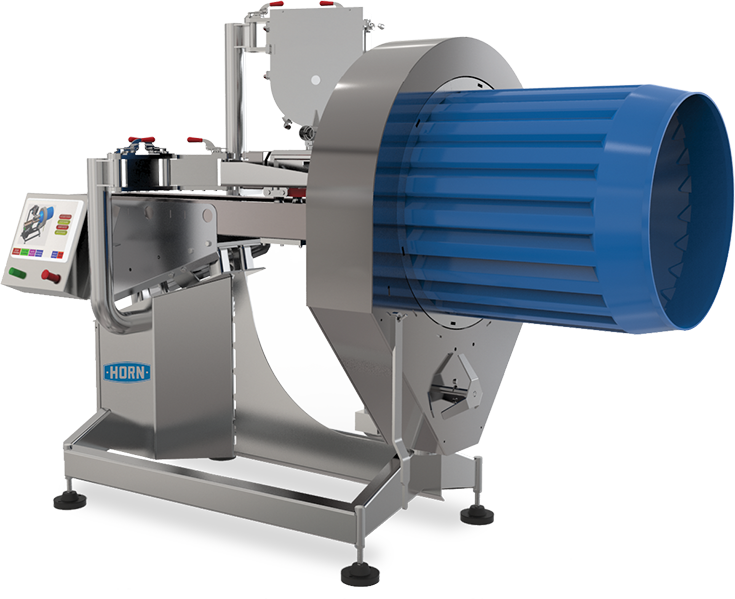

While base ingredients affect a product’s expansion characteristics, the proper machinery is critical to success. AC Horn Manufacturing has created a puffer that is a variant of the original Manley popcorn popper. The principles of manufacturing use high heat and a short dwell time to puff a preprocessed pellet.

Raw pellets are manufactured on an extruder with a combination of moisture, temperature and pressure. Grains, flours and powders are the typical ingredients. Historically these pellets were fried, however a process similar to popcorn processing led to the use of hot air instead. Using an extruder to combine moisture, temperature and pressure, the pellet is puffed with air instead of oil. This leads to a product with a longer shelf life because you eliminate the possibility of oil rancidity.

Pellets can be transformed into limitless sizes and shapes, but the equipment design must be flexible enough to handle this wide range of shapes and formulas. Horn equipment is built with these variables in mind and includes a control panel to help manage the multiple variables. Our puffer will produce a wide array of pelletized products. However, it generally does require fine-tuning at the manufacturing facility to achieve maximum efficiency for any given product.

The increased demand for healthier snacks in some markets has led to an increase in inquiries for puffers. Uniquely, some of the puffers sold by Horn act as dual-purpose machines. Though sold as a puffer, the machine can also switch to process air-popped popcorn with minimal changeover time.