Japanese Peanut Equipment

Japanese peanuts, called “cacahuates japoneses” in Mexico where the snack originated, have crossed the border to entice fans worldwide with their savory—and sometimes spicy—allure.

The product’s name stems from a blend of its creator’s heritage and his location. A Japanese immigrant living in Mexico City invented this nutty confection in the late 1940s, first selling them in La Merced Market. He enrobed a peanut in a crunchy, thin shell made of wheat flour mixed with a bit of soy sauce.

Japanese peanut fans in Mexico usually sprinkle the nuts with chili powder and/or fresh lime juice before eating. While the traditional product relies on wheat flour for the outer coating, other varieties of flour such as rice are sometimes used. Lately, developers have added more and varied spice blends to the dough coating to give the product a bit of a kick.

Processing equipment

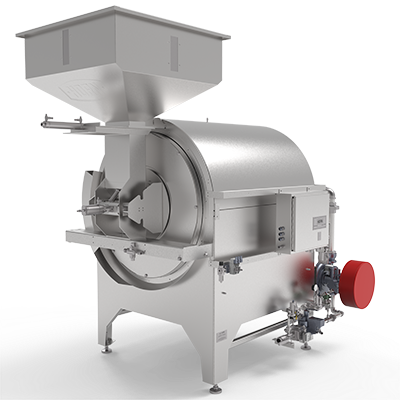

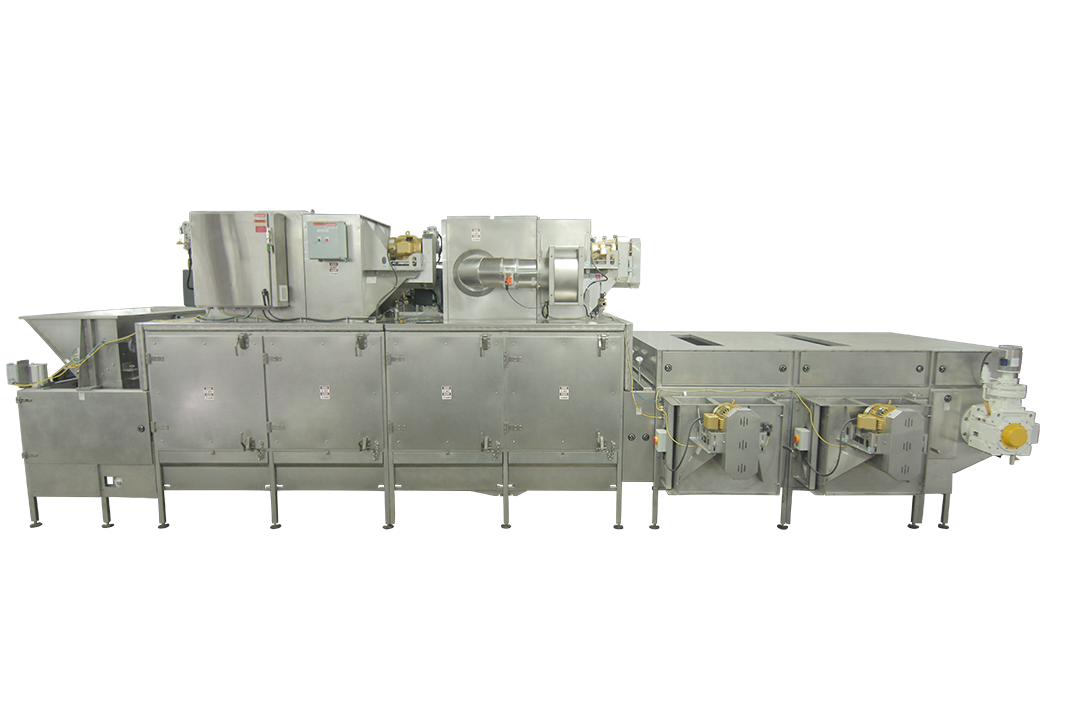

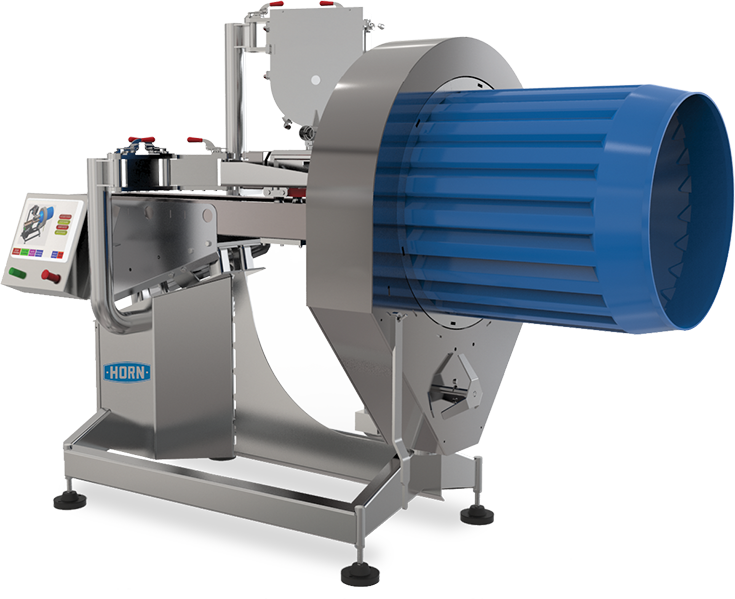

The dough covering was applied to the peanuts manually for years, until 10 years ago when AC Horn Manufacturing developed one of the first continuous lines for automatic production. The company has since sold multiple lines into Mexico and Latin America.

After its initial application, the dough coating on the peanut is relatively soft. If the product is processed using a conveyor belt, the dough flattens the round shape of the product. To preserve the round shape, Horn equipment uses a rotary heating device instead of a belted oven where the product is static as it moves through the heating zone. A rotary dryer keeps the product tumbling and moving as it is being heated.